EVOLVE Foresite

Operations Management Platform

UNIFIED ON ONE PLATFORM

Improved operations and alignment with the BIM Department and Fabrication Shop will save thousands of labor hours in the field.

SHOP

Shop BOM

Shop BOM

Issues requisitions

Issues requisitions

Call for delivery

Call for delivery

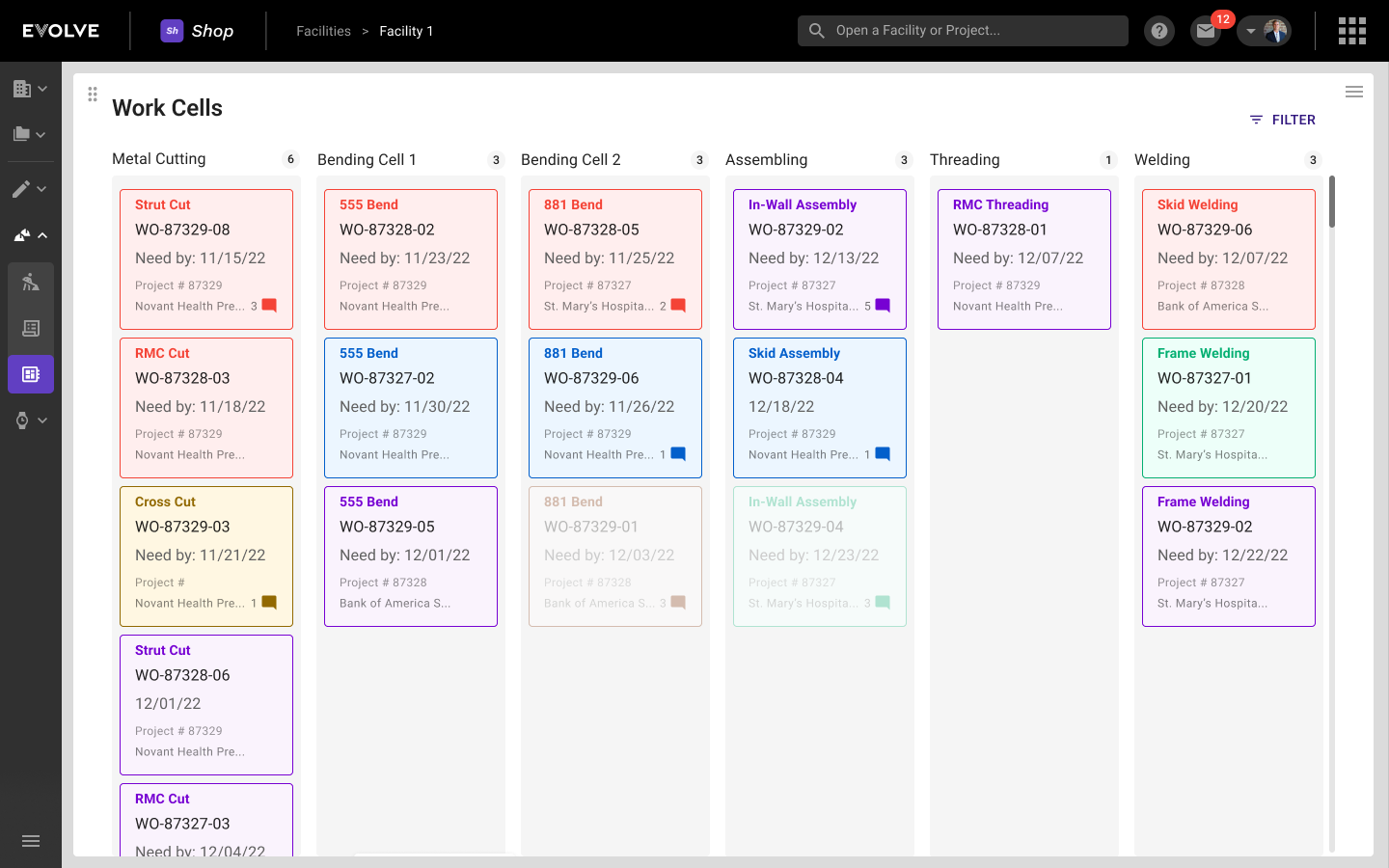

Work orders

Work orders

Work cell queues

Work cell queues

Fabrication tasks

Fabrication tasks

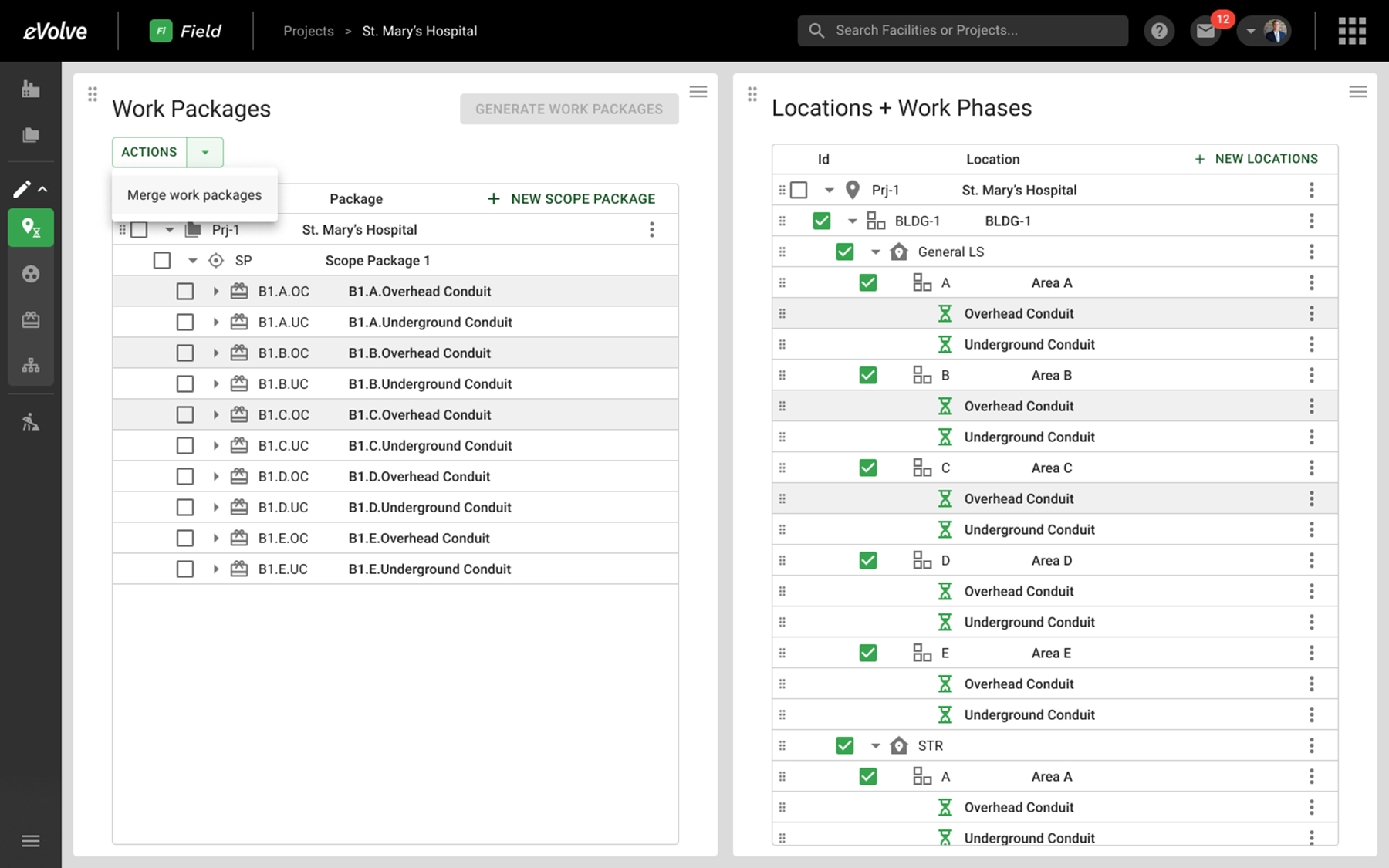

FIELD

Project setup

Project setup

Field BOM

Field BOM

Issue requisitions

Issue requisitions

Call for delivery

Call for delivery

Production tracking

Production tracking

Productivity tracking

Productivity tracking

DESIGN

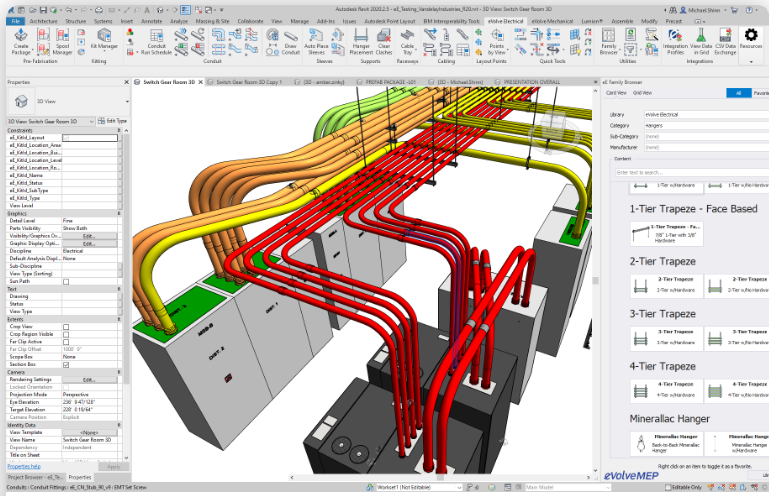

Fabrication rules

Fabrication rules Fab ready model

Fab ready model Locations/kitting

Locations/kitting

PROCURE

Fabrication rules

Fabrication rules Fab ready model

Fab ready model Locations/kitting

Locations/kittingPLATFORM OVERVIEW

Fab Shop benefits include clear visability for faster production and increased accuacy. As well as model utilization and a reduction in waste and rework.

DESIGN MODULE

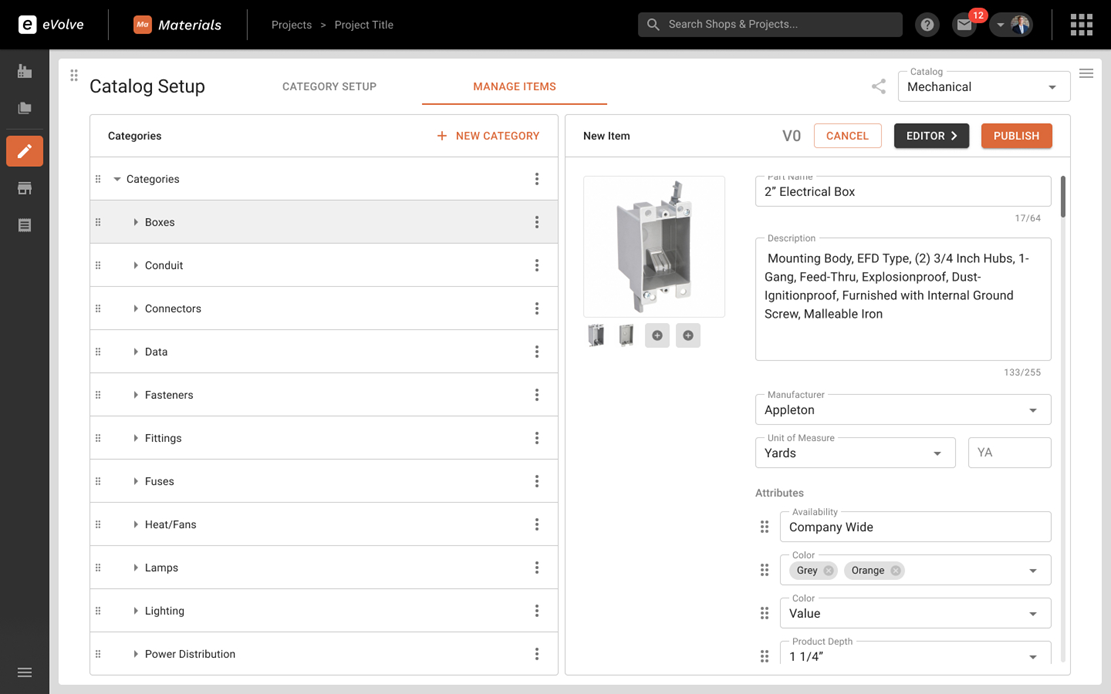

The BIM Design Department allows you to detail tools and automate. As well as manage your content library and results in less rework.

Spend less time waiting for materials to arrive and maximize the use of your hours. Increase visibility into what has arrived and what hasn’t.

The Procurement Module clears up visibility for faster production and increased accuracy. Ultimately resulting in improved model utilization and a reduction of waste and rework.