The 2023 EVOLVE Ultimate Guide To

Autodesk Revit

Autodesk Revit is being used all across the industry in a variety of ways. Read on to get an in-depth look at the benefits of Autodesk Revit.

The 2023 EVOLVE Ultimate Guide to Autodesk Revit Guide Table of Contents

What is BIM and Why Do You Need It?

What is BIM and Why Do You Need It?

In the 2000’s BIM was introduced, and it revolutionized how the construction industry was using technology. Building Information Modeling (BIM) is a digital representation of a building or structure that allows for the management and coordination of information. BIM uses 3D modeling software to create a virtual model of the building, which can be used for design, construction, as well as maintenance planning. BIM also allows for the integration of information such as materials, cost estimates, and energy analysis. It is becoming increasingly popular in the architecture, engineering, and construction industries to improve collaboration, reduce errors, and increase efficiency.

Building Information Modeling (BIM) is important for several reasons:

Improved Collaboration: BIM programs allows architects, engineers, and contractors to work together on a project in a coordinated and efficient manner. Using a common model and data allows design conflicts and inconsistencies to be identified and resolved early in the project.

Better Coordination: BIM encourages better coordination of all aspects of a project, including architectural, structural, mechanical, electrical, and plumbing systems. This can help to ensure that all systems work together seamlessly, and that construction is completed on time and within budget.

Increased Productivity: Many BIM programs have automation features for tasks such as schedule management and quantifying materials. This can save time and increase productivity, allowing projects to be completed more quickly and efficiently.

Better Quality Control: BIM allows users to verify and validate the design and construction of a project, helping to ensure that the final product meets all specifications and standards.

Better Facility Management: With BIM it is easier to verify and validate the design and construction of a project. This ensures that the final product meets all specifications and standards.

Better Facility Management: BIM provides a detailed digital representation of a building that can be used for facility management and maintenance. Better models make for more effective scheduling of maintenance and repairs and can help to identify potential problems before they become critical.

Sustainable Design: With better models it is easier to evaluate the environmental impact of a building design and to identify ways to make it more energy-efficient and sustainable.

Cost Savings: BIM can help to reduce costs by identifying potential problems early in the design process, reducing the need for change orders and rework during construction, and providing a more accurate cost estimate.

An Introduction to Revit

Autodesk Revit is the world’s leading software tool for the BIM process. Revit is a comprehensive software package that supports the entire building design and construction workflow, from conceptual design to construction documentation and project management. It allows users to create intelligent 3D models that represent the physical and functional characteristics of a building or structure. The models can be used for a variety of purposes, including visualization, analysis, and construction documentation.

Revit also provides a range of analysis and simulation tools that enable users to evaluate the performance and behavior of their designs in real-time. For example, users can perform energy and lighting analyses, structural and thermal analyses, and even simulate the movement of people and objects within a building.

Collaboration is also a key focus of Revit, with tools that allow users to share their work with others in real-time, regardless of their location or device. This facilitates teamwork and communication among project stakeholders, helping to ensure that everyone is on the same page and that project goals are met on time and within budget.

Revit is widely used in the architecture, engineering, and construction (AEC) industry, and has become an essential tool for building design and documentation. It helps to streamline the design process, reduce errors and rework, and improve communication and coordination among project stakeholders.

Revit 2023 was one of the most significant releases in years. New features included better search functionality, improved hardware setup, 3D measuring, structural analytics, and more.

One of the most sought guides for Revit users is the system requirements to run the software efficiently. In System Requirements for Revit 2023, you’ll find recommendations for entry-level configuration, value configuration, and performance scenarios involving large, complex models. Revit 2023 can suit a variety of configurations and needs.

If you’re using Revit 2023, you benefit from:

- Improved Hardware Setup

- Automatically enabled tag leader

- Assisted association for analytical modeling

- Auto-orient part to matching connector

- Structural analytical to physical model automation

- New DACH Structural Families

- And more!

Making the Switch to Revit

These days, implementing a BIM workflow is significantly different from implementing a CAD workflow back in the 1980s. When firms began transitioning from manual drafting to CAD, new tools had to be learned, but the basic process of generating construction documents was still based on the same rules of drafting that had been in place for decades or longer. Teams traded in parallel bars, triangles, leroy sets, and all of the other paraphernalia that enabled more efficient drafting. Now BIM is taking it a step further.

When moving from Fabrication to Revit, there are ways to make the transition successful:

- Get prepared - Familiarize yourself with the Revit interface and basic tools. Attend Revit training classes or tutorials.

- Make a communication plan - Learn how to collaborate with other team members using Revit's built-in collaboration tools. Then set clear guidelines and expectations for your team.

- Start small - Gain experience working with Revit with small-scale projects.

- Take advantage of plug-ins and add-ons. – The Autodesk app store has a wide variety of plug-ins specific to help meet specific needs. Check out 360 Sync to help you with file management. EVOLVE is an additional software option that syncs with Revit to empower MEP contractors with features that are catered to their specific needs.

- Make the commitment to Revit and stick with it – With so many features and capabilities Revit may initially be intimidating. Continuously practice and seek out new learning opportunities to improve your Revit skills.

5 Common Mistakes to Avoid in Autodesk Revit

Autodesk Revit is a powerful software tool for MEP design, but it can be complex and overwhelming for those who are not familiar with it. Here are a few common mistakes to be aware of so you can get the most out of the program:

When moving from Fabrication to Revit, there are ways to make the transition successful:

- Set Up Templates Correctly: One of the most significant benefits of Revit is its ability to automate repetitive tasks, but this feature is only useful if the templates are set up correctly. Failure to do so can lead to inefficiencies and inaccuracies in the design. It's important to take the time to set up the templates correctly to avoid these issues.

- Overcomplicating the Model: While Revit is a powerful tool, it's important not to overcomplicate the model. This can lead to slow performance, errors, and a lack of clarity in the design. It's important to strike a balance between the level of detail and the performance of the model.

- Use Best Practices for Collaboration: Collaboration is essential in MEP design, and Revit provides excellent tools for this. Within Revit it is important to use best practices for collaboration to avoid issues. For example, not properly managing shared parameters can lead to inconsistencies in the design, while not using work sharing can lead to conflicts between different team members.

- Understanding Workflows: Revit has many features and capabilities, but it's essential to understand the workflows that are best suited for MEP design. Failure to understand workflows can lead to inefficient use of the software, and engineers may miss out on many of its benefits. It's important to take the time to learn and understand the workflows that are most effective for MEP design.

- Use Families Correctly: Families are an essential part of Revit, and they allow engineers to create custom objects and components that can be used across projects. However, families can also be misused or not used correctly, leading to errors and inconsistencies in the design. It's important to understand how to use families correctly to ensure that the design is accurate and efficient.

Collaboration is

essential in MEP design

Revit for Prefabrication

Prefabrication is increasingly in the news as companies strive to get control of escalating costs, the labor shortage, tighter schedules, and job site safety. Prefabrication provides better working conditions, more precise materials usage, easier staging, better labor coordination, and increased safety.

Revit is a great investment if your team is looking to scale your fab and prefab efforts. Your virtual design and construction (VDC) team can create 3D models and easily share them with Revit’s in-app communication. Models can then be used to plan and coordinate the individual components which need to be completed in the shop.

Revit can be used to generate detailed fabrication and assembly drawings, which can be used by prefabrication manufacturers to produce the necessary components. The software can also be used to track the fabrication process and to manage the delivery of prefabricated components to the construction site.

In this video case study with Cleveland Electric, you learn how their organization was able to scale their fab shop by leveraging the power of Revit with EVOLVE.

By using Revit, contributors from allteams can share and save designsfor the same project.

Prefabrication is a natural fit for MEP trades. It improves productivity, lowers project costs, reduces schedule time, improves quality and safety, and improves recruiting response. Revit takes the best parts of traditional fabrication workflows and combines them with the best platform for the BIM process. It can be made even simpler through the use of EVOLVE. EVOLVE provides the essential tools to take a Revit fabrication model to manufacture and install with streamlined production.

Additional modules are available to specifically support the BIM-to-shop-to-field relationship. One would be EVOLVE. Read on to learn more about how EVOLVE pairs with Revit.

Check out the EVOLVE Ultimate Guide to Prefabrication for an in-depth examination of the prefab process. Download the eBook to learn about the various ways prefab is being used, get specifics on how you can see ROI from prefab, and read about the best tools and tactics for successful prefabrication.

Revit takes the best parts of

traditional fabrication

workflows and combines

them with a high-capacity

platform for the BIM process.

Revit Across Different Roles

By using Revit, contributors from all disciplines can share and save work for the same project. Here is how Revit can be leveraged by different roles across AEC and MEP organizations.

Architects

Architects can use Revit, a building information modeling (BIM) software, to create detailed 3D models of buildings and their systems. They can use the software to design and document the building, including the layout of rooms, the placement of doors and windows, and the location of electrical and mechanical systems. Revit also allows architects to create and manage construction documents, such as floor plans, elevations, and sections, and to create schedules and material lists. Additionally, architects can use Revit to collaborate with other members of the design team, such as engineers and contractors, and to analyze building performance.

Engineers

Revit allows engineers to increase detail and accuracy in a model. It has state-of-the-art features specifically for engineers such as creating geometry and working in 3D views. You can immerse yourself in a design and easily share that design with clients through Revit. You can experience your project from the inside out. When designing in 3D, you can see an actual connection instead of a symbol for the connection. Software enhancements now allow complex piping networks in parallel, pump networks and separators in flow calculations and routing solutions.

Designers and Detailers

Designers and detailers use Revit to create detailed 3D models of buildings and their components. They can use the software to design and plan the layout of a building, including the placement of walls, floors, ceilings, and other architectural elements. They can also use Revit to create detailed fabrication and construction drawings, such as floor plans, elevations, and sections. Revit can be used to perform building analysis and energy simulations, as well as to generate schedules and quantities for construction. Revit also enables team collaboration and is widely used in the AEC industry. Further, Revit supports best practices for manipulating geometry, working with survey data, and handling multiple buildings.

Mechanical, Plumbing, and Electrical Contactors

MEP (mechanical, electrical, and plumbing) contractors use Revit, a building information modeling (BIM) software, to create detailed 3D models of building systems such as HVAC, electrical, and plumbing. They use these models to design, plan and document the building's MEP systems. This allows them to coordinate with other trades and ensure that the systems are properly integrated with the building. Contractors can use the 3D models to generate accurate cost estimates, fabrication drawings, and construction documents. Revit also allows MEP contractors to simulate and analyze building system performance, which can help with energy efficiency and sustainability efforts.

EVOLVE is a Revit add-on that many MEP contractors are using. Read on for more information on how MEP contractors use EVOLVE and Autodesk Revit to empower their teams.

Revit for MEP Contractors

The specialized software tool EVOLVE is propelling the MEP industry forward by harnessing the power of Revit. A combination of software and services enables a faster detailer workflow, fewer errors, smarter use of skilled labor, and higher quality. Leaders in the mechanical, electrical and plumbing industries have used EVOLVE to improve productivity, enhance quality and enhance the ability to sell more work.

Revit software produces consistent, coordinated model-based building designs and documentation. It automatically updates floor plans, elevations, sections, and 3D views. Revit uses 3D visualization to “see” a building before construction even begins. Combined with the power of EVOLVE, Revit is a top choice for BIM design software for MEP teams.

Revit features for the mechanical, electrical and plumbing design process include:

HVAC design and documentation - Complex duct and pipe systems can be designed to express intent. Duct and pipe systems can be modeled with mechanical design content.

Electrical design and documentation - Electrical systems can be designed, modeled and documented. Electrical loads can be actively tracked throughout the distribution system.

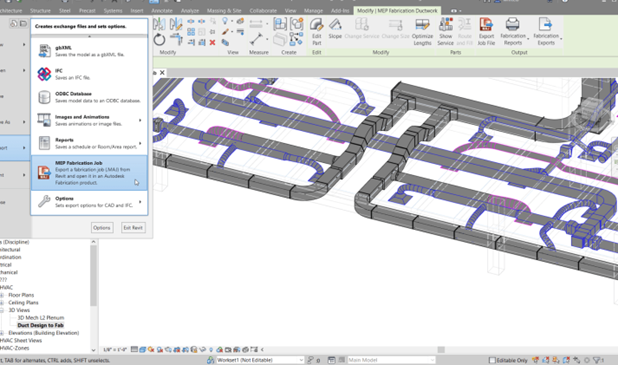

MEP fabrication detailing - Fabrication-ready models can be created in Revit. MEP LOD 400 components can be modeled and coordinated.

Advanced analysis - Centralized access to performance data and advanced analysis engines allows building performance to be optimized.

Fabrication service conversion - Design-level model elements can be converted to construction LOD elements.

Fabrication documentation - The model layout can be documented more effectively. Fabrication elements can be documented, scheduled and tagged.

Plumbing design and documentation - Create sanitary plumbing systems with sloped piping and layout piping systems to design and document intent.

Top Reasons Why MEP Contractors Need Revit

Revit has many features to support BIM design, but it also provides an array of other features to help optimize your team.

Improved Collaboration: Revit provides powerful collaboration tools that allow multiple team members to work on the same model simultaneously. This can help to improve communication and avoid errors.

Increased Efficiency: Revit automates many of the tedious and repetitive tasks in MEP design, allowing contractors to work more efficiently and focus on more critical tasks.

Better Visualization: FRevit provides excellent visualization tools, allowing contractors to create detailed 3D models that can help to communicate design concepts and identify potential issues before construction begins.

Enhanced Accuracy: Revit allows contractors to create accurate models that take into account real-world conditions, helping to reduce errors and costly rework.

Improved Coordination: Revit allows contractors to coordinate with other trades more effectively, ensuring that all components of the design fit together seamlessly.

Better Cost Control: Revit allows contractors to create detailed cost estimates that take into account every aspect of the design, helping to improve cost control and avoid unexpected expenses.

Enhanced Flexibility: Revit allows contractors to make changes to the design quickly and easily, helping to improve flexibility and adaptability to changing project requirements.

Improved Productivity: Revit's powerful tools and automation features can help contractors to work more efficiently, allowing them to take on more projects and increase productivity.

Better Quality Control: Revit allows contractors to create detailed models that can be analyzed and tested for quality, helping to ensure that the final product meets the highest standards.

Future-Proofing: Revit is constantly evolving, and contractors who adopt the software now will be better positioned to take advantage of future updates and features, helping to future-proof their business.

Revit for the Electrical Industry

EVOLVE Electrical support Revit with features and additions that are specific to the goals and needs of electrical contractors. As a Revit add-on, EVOLVE Electrical enables more accurate analysis and predictions and gives your team the tools they need to complete projects faster without ever sacrificing quality.

- Conduit run schedules which allow the user to easily assign run ID’s and data to conduits in Revit models. The program will then determine the conduit run lengths for wire ordering and procurement.

- Conduit-optimized bend tools to automate the process of designing conduits, couplings, and racks to save you hours

- Seamlessly assign spool designation and instantly produce prefab sheets with 3d views and a BOM

- The hanger placement features automate multi-tier trapeze rack placements with ease

- And so much more!

You can see a video of EVOLVE Electrical in action here! Or check out this page for more details and to get a live demo!

Revit for the Mechanical Industry

One tool that is backed up by real numbers and process statistics is EVOLVE Mechanical. EVOLVE Mechanicals pairs with Autodesk Revit to deliver a robust platform that helps mechanical contractors reach their business goals.

- When you add-on EVOLVE Mechanical to Revit you can experience all the great features of Revit with additional support that is designed specifically for the needs of the mechanical industry. A few of these revolutionizing features include:

- The EVOLVE Point Layout feature enables the user to create point layout drawings and export points to a CSV or TFL file

- The EVOLVE Element Filter is a powerful tool that allows you to select, isolate, isolate temporarily, show, hide, make half-tone, and make elements transparent, based on rules you define

- Spooling has never been easier as users can quickly select elements, assign a spool designation, then produce prefab sheets that include 3D views, plan & elevations, and a BOM in a matter of minutes

- Plus many more!

Watch this video to see a demonstration of the EVOLVE Mechanical product. Learn more and get a demo with our team here!

Additional Resources

- Autodesk Revit Support

- Autodesk Revit Templates

- Autodesk Revit Tutorial Videos

- Autodesk Community Forums

- Autodesk App Store

- Youtube featuring demos for electrical contractors using Revit and EVOLVE

- Youtube featuring demos for mechanical contractors using Revit and EVOLVE

Autodesk Revit Blogs

A Checklist for Quality Control of Mechanical BIM Drawings

EVOLVE Mechanical and EVOLVE Electrical 7.4 Introduces New Features to Elevate BIM Efficiency for MEP Projects

EVOLVE, the cutting-edge BIM software designed to seamlessly integrate with Autodesk Revit, is announcing the launch of EVOLVE Mechanical and EVOLVE Electrical Version 7.4.