Designing a paperless prefab shop is easier than you think.

How to start a prefabrication shop with digital workflows, taking on your prefab shop and going digital, designing a paperless shop is easier than you think.

Coming soon to a Shop near you

The United States Prefabricated Buildings Market size is estimated at USD 40.91 billion in 2024, and is expected to reach USD 54.59 billion by 2029, growing at a CAGR of 5.94% during the forecast period (2024-2029).

Eco-Friendliness

Traditional construction methods often result in excess materials and increased waste.

Prefab buildings are primarily constructed in a factory, reducing waste and allowing for the recycling of leftover materials for other projects.

Shortened Timelines

Prefab construction benefits from better upfront planning and eliminates on-site weather and subcontractor scheduling delays.

Simultaneous fabrication of multiple pieces contributes to quicker construction timelines compared to traditional methods.

Consistent Quality

Traditional construction quality can vary based on local resources and the skills of tradespeople.

Prefab construction, taking place in a controlled environment with standardized processes, ensures consistent and precise quality in the sub-assemblies of the structure.

Define Business Focus

Explore Industry Segments

Study leading companies like U.S. Modular Group East and insights from platforms like Business.com. Analyze success stories such as Michelle Kaufmann’s in prefab housing for valuable lessons.

Understand the financial nuances between mobile and modular homes, with a focus on modular homes as long-term investments.

Identify Market Niche

Consumer Research

Conduct research on consumer needs specific to prefab homes, including the requirement for land ownership. Highlight the benefits of prefab homes, such as speed of construction and cost efficiency. Examine competitor strategies to carve out a unique market niche.

Develop a Business Plan

Strategic Planning

Articulate the company’s mission and vision. Provide a detailed three- to five-year financial forecast. Commit to sourcing recyclable and eco-friendly materials as part of the sustainability focus.

Source Materials and Machines

Procurement Strategy

Engage in comprehensive research to find the best sources for materials and construction machinery. Evaluate the balance between price, quality, and supplier reputation before finalizing contracts. Consider innovative materials like bamboo for cost and environmental benefits.

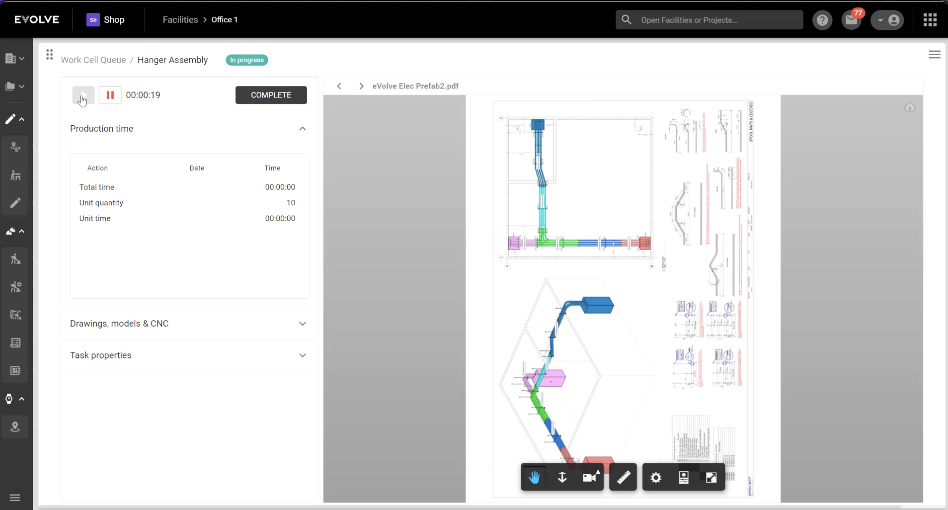

Planning Your Shop Space

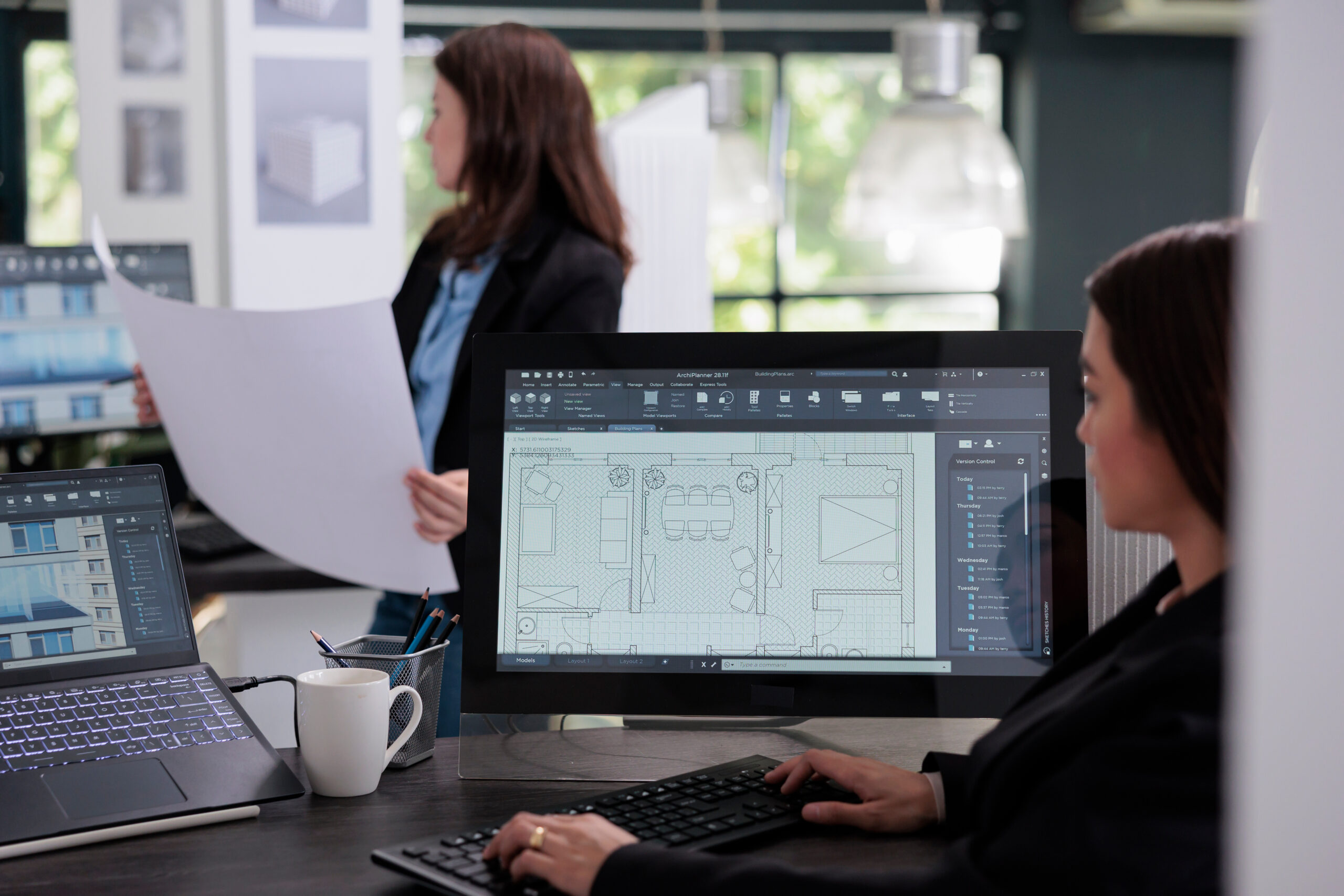

Efficient Use of Space

Utilize vertical storage solutions and invest in durable containers for material safety. Ensure proper workshop insulation and efficient heating and cooling systems. Plan for a comprehensive electrical system to accommodate lighting and power needs. Design workstations to fit the operational flow, incorporating digital tools for streamlined processes.

The 2024 Ultimate Guide to Prefabricated Construction for Operations Managers