Despite its promises of efficiency and cost-effectiveness, many in the construction industry find themselves grappling with obstacles that prevent prefabrication from being as successful as possible. While prefab construction offers numerous advantages, such as reduced construction time, decreased material waste, and enhanced quality control, there are underlying factors that can impede its success.

Let's delve into the real reasons behind the struggles encountered in prefabrication productivity and examine the ways you can tackle these challenges.

Lack of visibility into shop operations

Most prefabrication shop managers get information on how the shop is performing by walking the floor. They have to physically go to each workstation, or go to where materials are stored to see for themselves what the state of things are. This is painstaking work!

Relying solely on manual observation is limited and inefficient. It lacks the depth and precision required to identify underlying inefficiencies, potential bottlenecks, or areas ripe for optimization. It consumes valuable time and resources that could be better used for strategic planning and problem-solving.

Implementing digital tools like BIM and prefabrication management software can streamline workflows, improve accuracy, and reduce waste - impacting your business and the environment. Look for a prefab shop solution that offers a user-friendly platform that digitizes the prefab process, enabling paperless operations and better visibility into project data and workflows. With better reporting and data on prefab operations management can make informed decisions on labor, delivery schedules, and more.

Communication Between Departments

Communication between prefabrication shops, BIM design teams, and the field can be challenging due to several factors. Each team may have distinct priorities and perspectives shaped by their specific roles and responsibilities. All three teams may use different software platforms and tools, leading to compatibility issues and data transfer challenges. Without interoperable systems or standardized protocols for sharing information, communication breakdowns are more likely to occur.

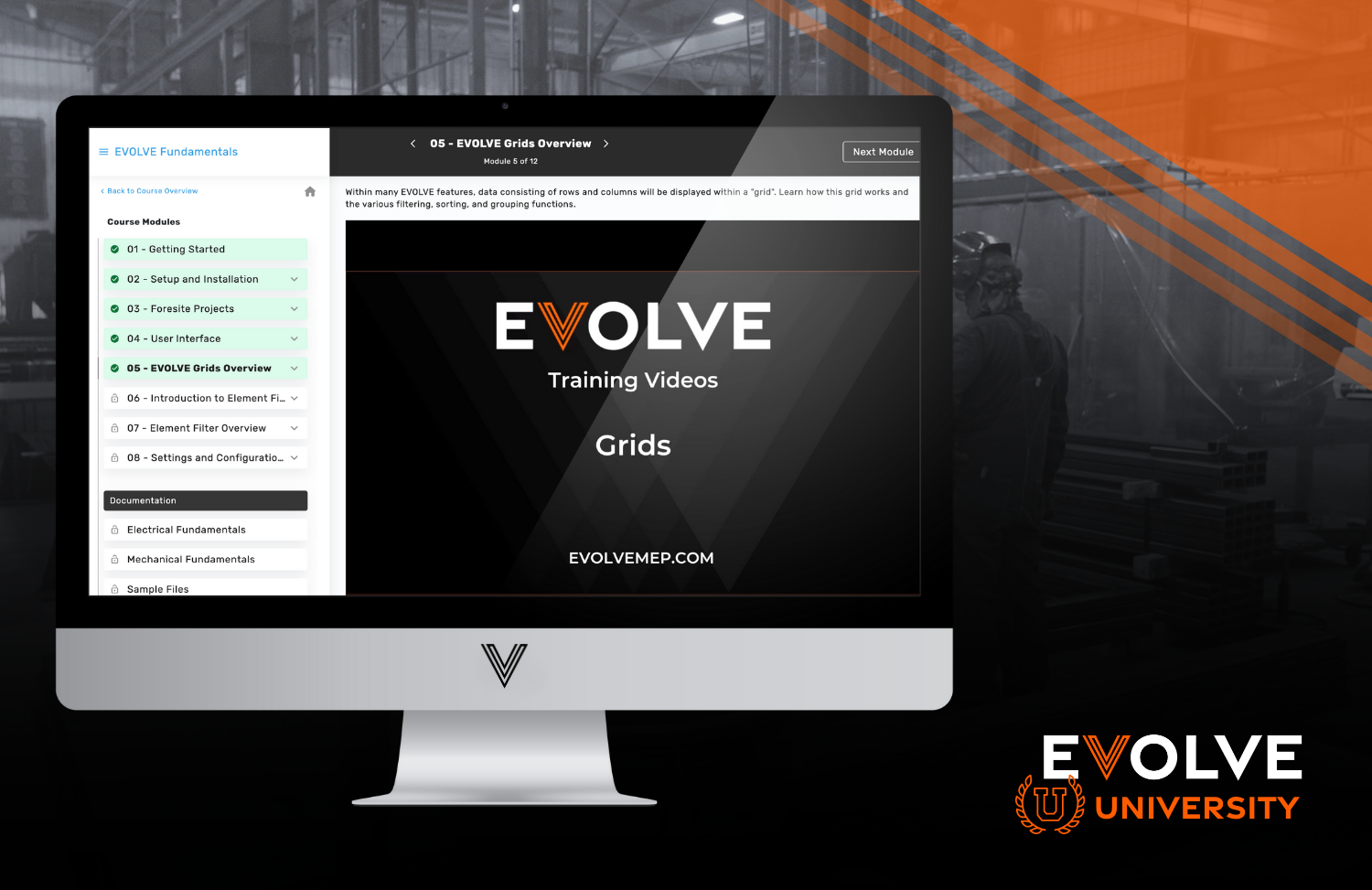

Effective communication requires seamless integration of workflows across prefabrication, design, and field activities. Programs like EVOLVE Shop ensure that anyone on your team can see the same information as everyone else.

For example- when an assembly is ordered through EVOLVE Shop, managers can attach models to the assembly along with the specifications for materials and the process for how it should be built. The employee on the shop floor can see their assignment on an iPad, and can get started without additional communication. Managers can track the progress of each assembly in order to make accurate schedules. The field foreman can use EVOLVE Shop to request prefab assemblies directly from the field.

Having everyone on the same platform will save you hours of time on back-and-forth communications. By overcoming communication barriers and fostering closer collaboration between prefabrication, BIM, and field teams, construction projects can achieve greater efficiency, accuracy, and overall success.

By embracing digital transformation, leaders can improve their prefabrication shop operations to become a lean, mean, productive machine! Get a demo with the EVOLVE team today.

Let's delve into the real reasons behind the struggles encountered in prefabrication productivity and examine the ways you can tackle these challenges.

Lack of visibility into shop operations

Most prefabrication shop managers get information on how the shop is performing by walking the floor. They have to physically go to each workstation, or go to where materials are stored to see for themselves what the state of things are. This is painstaking work! Relying solely on manual observation is limited and inefficient. It lacks the depth and precision required to identify underlying inefficiencies, potential bottlenecks, or areas ripe for optimization. It consumes valuable time and resources that could be better used for strategic planning and problem-solving.

Implementing digital tools like BIM and prefabrication management software can streamline workflows, improve accuracy, and reduce waste - impacting your business and the environment. Look for a prefab shop solution that offers a user-friendly platform that digitizes the prefab process, enabling paperless operations and better visibility into project data and workflows. With better reporting and data on prefab operations management can make informed decisions on labor, delivery schedules, and more.

Communication Between Departments

Communication between prefabrication shops, BIM design teams, and the field can be challenging due to several factors. Each team may have distinct priorities and perspectives shaped by their specific roles and responsibilities. All three teams may use different software platforms and tools, leading to compatibility issues and data transfer challenges. Without interoperable systems or standardized protocols for sharing information, communication breakdowns are more likely to occur. Effective communication requires seamless integration of workflows across prefabrication, design, and field activities. Programs like EVOLVE Shop ensure that anyone on your team can see the same information as everyone else.

For example- when an assembly is ordered through EVOLVE Shop, managers can attach models to the assembly along with the specifications for materials and the process for how it should be built. The employee on the shop floor can see their assignment on an iPad, and can get started without additional communication. Managers can track the progress of each assembly in order to make accurate schedules. The field foreman can use EVOLVE Shop to request prefab assemblies directly from the field.

Having everyone on the same platform will save you hours of time on back-and-forth communications. By overcoming communication barriers and fostering closer collaboration between prefabrication, BIM, and field teams, construction projects can achieve greater efficiency, accuracy, and overall success.

By embracing digital transformation, leaders can improve their prefabrication shop operations to become a lean, mean, productive machine! Get a demo with the EVOLVE team today.