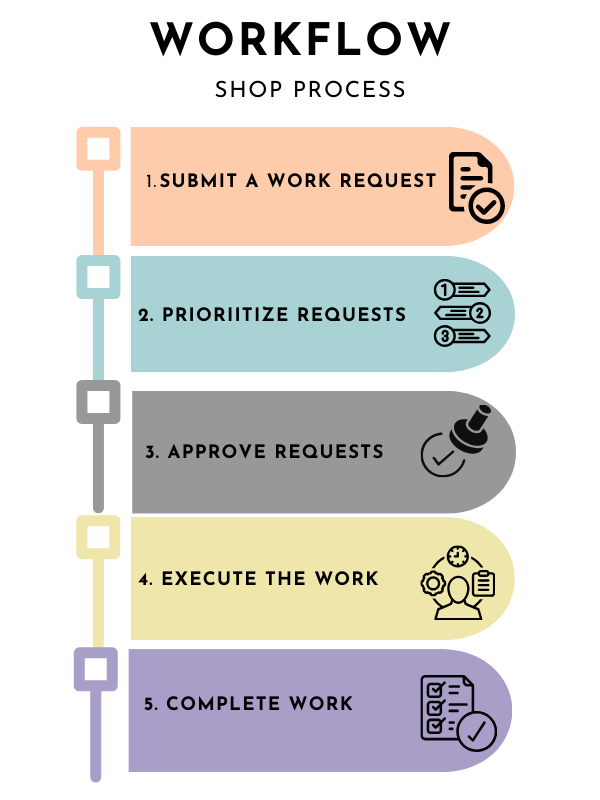

EVOLVE’s Shop Module is a powerhouse that drives production teams to enhance their effectiveness in the completion of work orders. Its basic workflow involves creating work requests from the field or design departments, submitting them to the fabrication facility, and managing the approval process through to the shop manager to completion. The system automatically generates work orders, prioritizes them, and records the completion of tasks on the shop floor.

EVOLVE’s Shop Module is a powerhouse that drives production teams to enhance their effectiveness in the completion of work orders. Its basic workflow involves creating work requests from the field or design departments, submitting them to the fabrication facility, and managing the approval process through to the shop manager to completion. The system automatically generates work orders, prioritizes them, and records the completion of tasks on the shop floor. Connecting Elements and Spool Drawings: The Shop system facilitates the connection and spool drawings directly to work orders and work requests to support a digital workflow on the shop floor. This can be achieved by sending spools to the Foresight project for mapping by the design team or shop manager.

Work Request Tracking and Management: Fab shop managers benefit from easy tracking, with a comprehensive view of the work request list, its statuses, and the ability to drill down into specific work requests. The system allows tracking of work requests with different statuses, highlighting delays with red statuses. Fab shop managers can open work requests, view orders, identify issues, and manage incomplete steps in the workflow.

Work Order Attachments: EVOLVE Shop includes the ability to add attachments at the work order level. Work orders can be organized using Kanban boards, calendars, and list views, enabling prioritization and task tracking and data-driven decision making.

Take full advantage of Shop for your prefabrication shop. Get a demo to see how EVOLVE Shop can be adapted to propel your shop forward. Watch our on-demand webinar to see the workflow processes in action.