Related Articles

EVOLVE Mechanical and EVOLVE Electrical 7.4 Introduces New Features to Elevate BIM Efficiency for MEP Projects

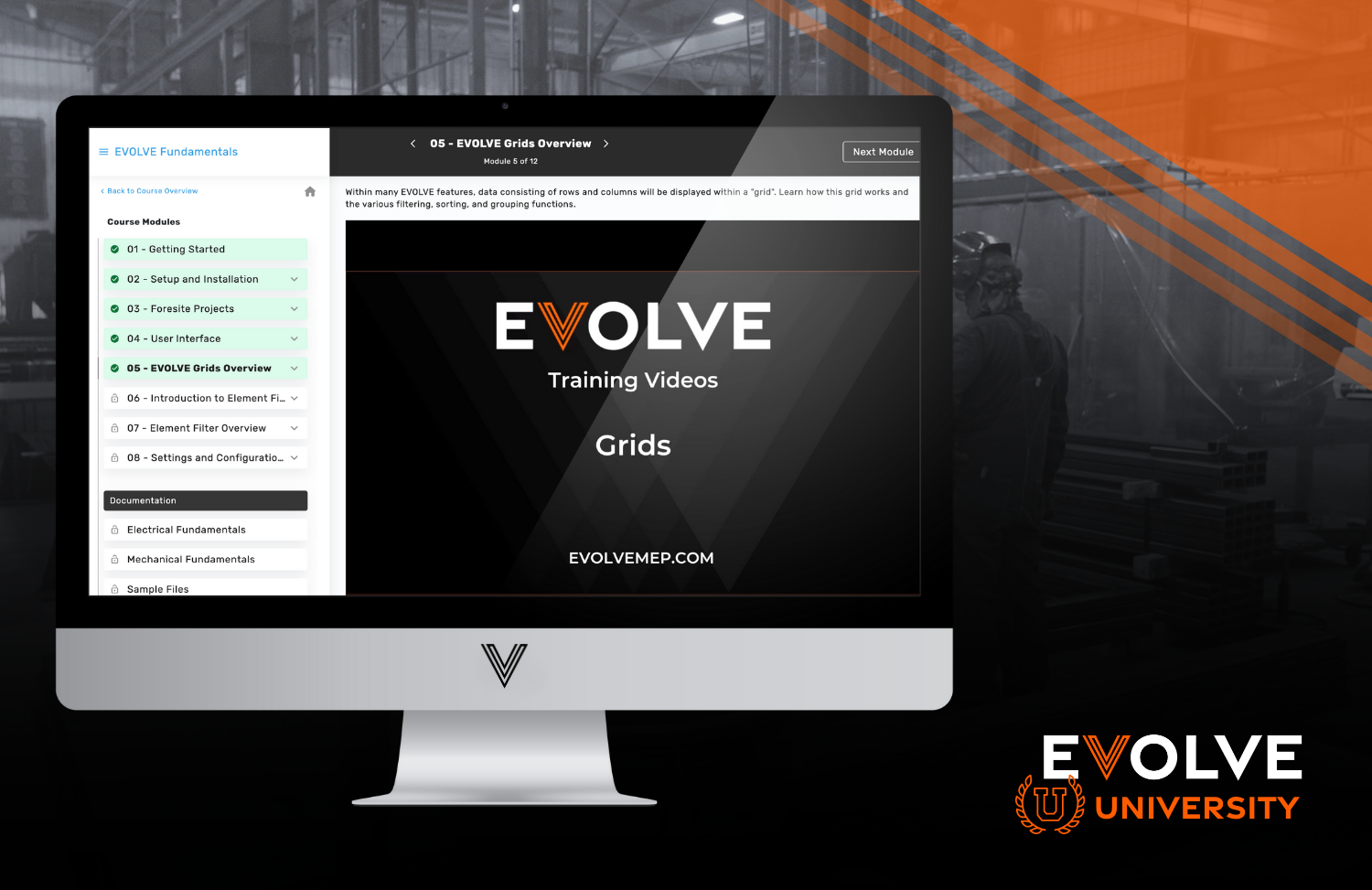

EVOLVE, the cutting-edge BIM software designed to seamlessly integrate with Autodesk Revit, is announcing the launch of EVOLVE Mechanical and EVOLVE Electrical Version 7.4.